Designs & Systems

Custom Fabrication

Automated Conveying Systems designs and builds Automated and Custom Equipment to meet our customers requirements. Here we see examples of heavy duty fabricated 4-wheel steer dollies.

These dollies were designed to withstand the rigors of automotive plant use. Shelf spacing, turning radius, dolly tracking and wheel protection were a few of the demands of this particular application.

ACS worked closely with our customer to determine the performance characteristics, then provide the structural and manufacturing design details to provide there dollies within budget and schedule parameters.

ACS provides complete systems, including design, fabrication, assembly and controls.

Customized solutions often require special equipment. Whether engineering a specialty conveyor, automating a product delivery system, or designing a secondary robot cell, Automated Conveying Systems can design and engineer the equipment you need. Our CAD department has access to our library of completed designs, bringing cost efficiencies and problem solving ideas to each project.

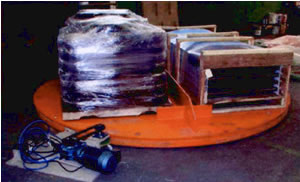

Turntables

Automated Conveying Systems designs and builds Automated and Custom Equipment to meet our customers’ specific requirements. Heavy Duty Low Profile Turntables are an example of ACS capabilities.

The example turntable shown is a two position table, designed to hold automotive part racks of roughly 4,000 lbs. each. This table -s roughly 12′ in diameter and is only 6″ tall. It uses an external friction drive motor and a pneumatic brake system.

Designed to be loaded and unloaded by forktruck, the top surface and bracketing are fabricated of heavy duty plate steel, specificalyl for the rigors of the automotive plant environment.

ACS provides complete systems, including design, fabrication, assembly and controls.

Custom Lift Tables

Whether your Scissor Lift requirements are Light duty, Standard Duty or Heavy Duty, ACS has the right Materials Handling Solutions.

For 20 years, ACS has been providing our customers with superior products that meet three criteria: Quality, Reliability and Affordability.

Let us help you with your next Lifting, Tilting, Rotating, or Upending project.

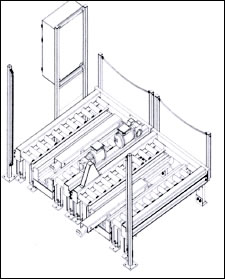

What is a Lift & Carry Transfer system?

“Lift & Carry” is a patented system to efficiently move and manage material loads without contact between pallets or containers on the conveying line. The system handles larger loads than traditional belt or roller conveyors, reduces maintenance costs, and prevents damage to the end users product.

The basis of the “Lift & Carry” conveying system is the “Lift & Carry” Cart. The Cart rides on tracks and physically lifts the pallet or container off the support rails, moves it to the destination point, and then gently sets the cargo back on the support rails. The Cart is equipped with sensors and controls that allow it to “think” for itself, find pallets or containers, and move them to an appropriate location.

“Lift & Carry” can move damaged pallets and containers easily; much improved over other conveyor types.

Lift & Carry

Standard Duty Lifts

Tilt Tables

Two “Lift & Carry” carts in tandem work as a team by exchanging cargo to increase throughput. Notice safety light screens are integrated into the system

Power Units & Controls

ACS offers a complete line of Professional Material Handling Controls implementation services including Electrical Engineering and Design, Control Panel Build, PLC and Relay Programming, Start Up services including Debug, Test, Run-Off, and Installation, and Documentation and Start-Up Support / Training.

Control Panel Build

ACS engineers, designs, and builds control panels in house, to insure that your system is implemented and operates correctly.

Our engineers will work closely with you to make sure that your control system meets the necessary functionality criteria to meet your requirements…on time…on budget.

PLC & Relay Programming

Whether your system requires a simple PLC Controller, or a sophisticated and detailed Relay Logic Control Panel, ACS has the solutions.

We have designed several Turn Key Systems, based on the requirements of our customers.

Hydraulic Power Units

If your system requires elevation changes, product turning, rotating, or tilting, ACS has the Controls capabilities to meet your needs.

We routinely incorporate Hydraulic Lifting, Tilting, and Rotating devices into our conveyance systems. These units can be designed as either Internal or External, with Electric and Pneumatic Motors.

Pneumatic Controls

Whether your system has Air Logic Accumulation, Pneumatic Blade Stops, Product Pushers, or some lifting, tilting, or rotating function, ACS can design, build, and implement the right Material Handling Controls System to meet your requirements.

Pallet Systems

Automated Conveying Systems designs and builds Automated and Custom Equipment to meet our customers specific requirements. The ACS Pallet Exchanger System automatically loads and unloads pallets or containers from dollies or trailers.

A tugger or AGV appoaches the Pallet Exchanger pulling a trailer or train with a conveyor deck. When the trailer/dolly is in position and confirmed by sensors on the pallet exchanger, the exchanger uses an arm to pull the pallet from the trailer onto a mating chain drvien conveyor. Loading pallets onto the trailer uses the opposite motion.

The pallet exchanger is an effective method to utilize dollies or trailers to move pallet or container loads of material through a facility, and integrate safer transport methods with conveying systems. ACS provides complete systems, including design, fabrication, assembly and controls.

Palletizing Systems

Pallet Conveyors

Pallet Exchangers are effective at quickly moving and loading/unloading pallets or containers throughout a facility